Projekt PrintCYC

High quality recyclates comparable to virgin material

The new premium recyclates showed excellent processability for the production of blown films, cast films and even biaxially oriented films which was 100 percent comparable to virgin material. Up to 100 percent recyclate in the inner layer of an three layered ABA film structure could be implemented successfully.

In Detail

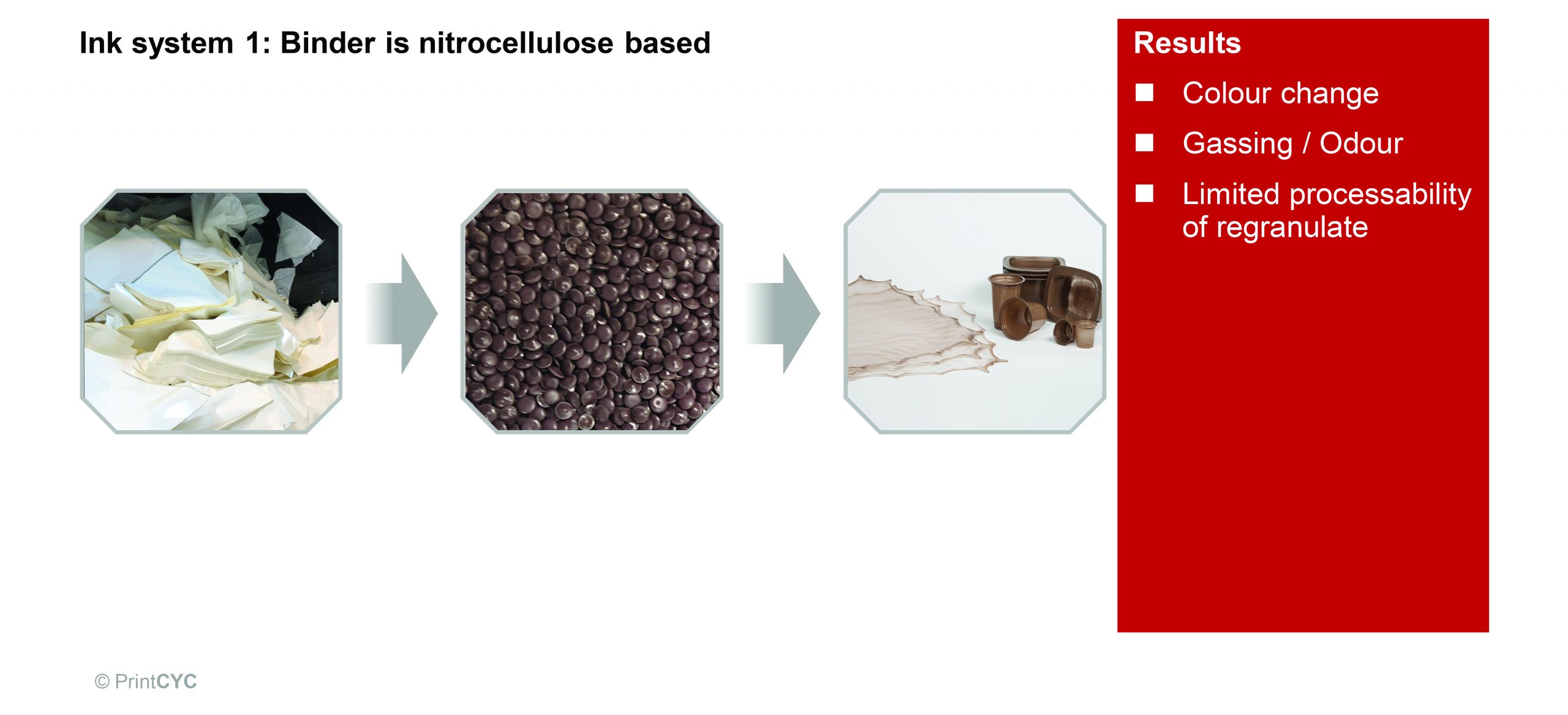

Market standard inks for plastic packaging

In phase 1 of the project, PP film and packaging samples containing > 50 % of PP recyclate could successfully be produced. The base material was printed biaxially oriented PP (BOPP) films on nitrocellulose (NC) based ink formulations. Nevertheless, the recyclate quality was not completely satisfying regarding material properties like colour, smell and processability.

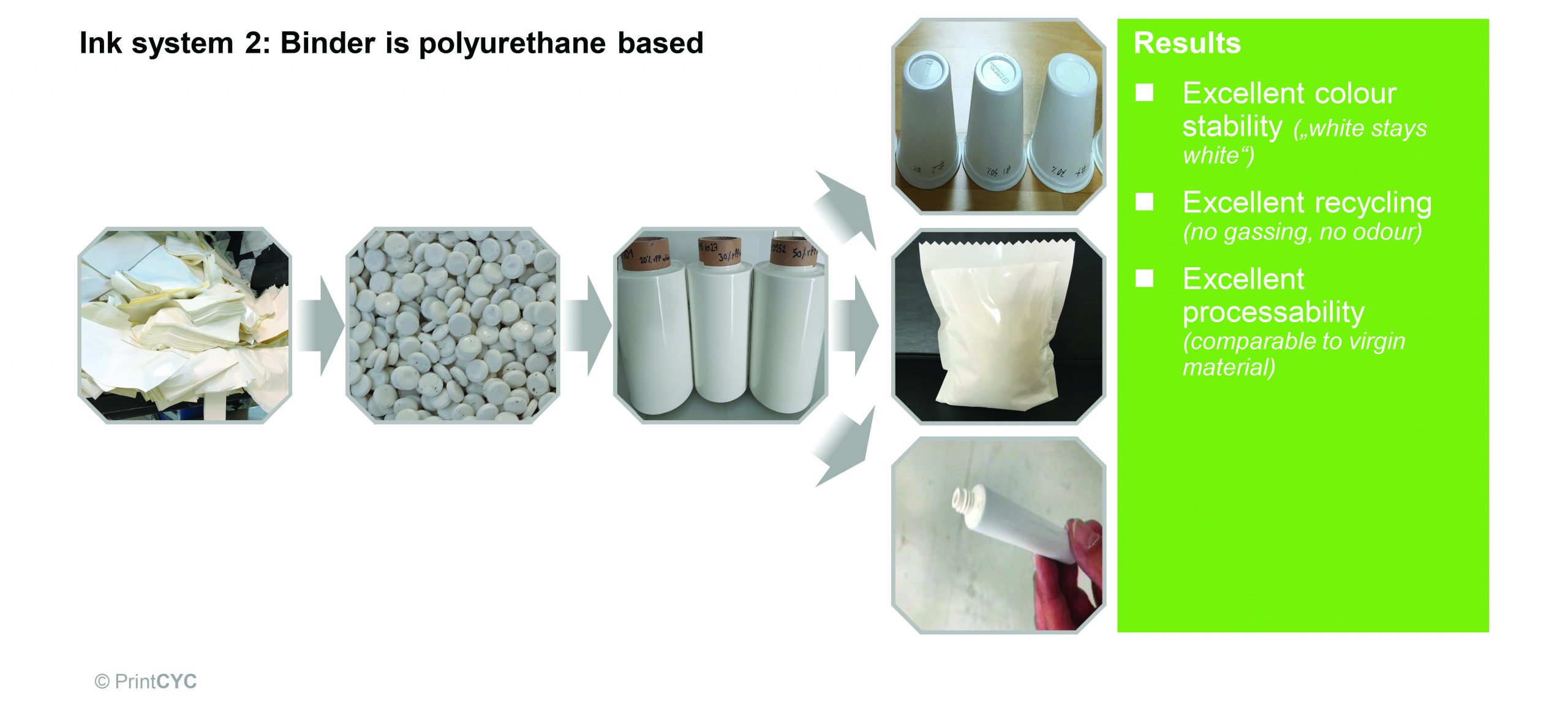

PU based ink system makes the difference

Based on these first promising results from phase 1, PrintCYC members strived for further improvement by testing alternative ink formulations for printing on BOPP and Low Density Polyethylene (LDPE) films. Switching to a polyurethane (PU) based ink system in flexoprinting in phase 2 resulted in significant improvements of the mechanical recycling process on a production line which is typically used for reprocessing printed film waste materials in practice.

Due to high temperature resistance of the inks (Temperature > 240°C), neither volatile byproducts, nor odour or gels were observed, leading to a new class of premium quality recyclates, showing colour stable properties. A first environmental impact assessment showed decreased greenhouse gas emissions due to lower energy consumption of mechanical recycling of LDPE films compared to virgin material production.